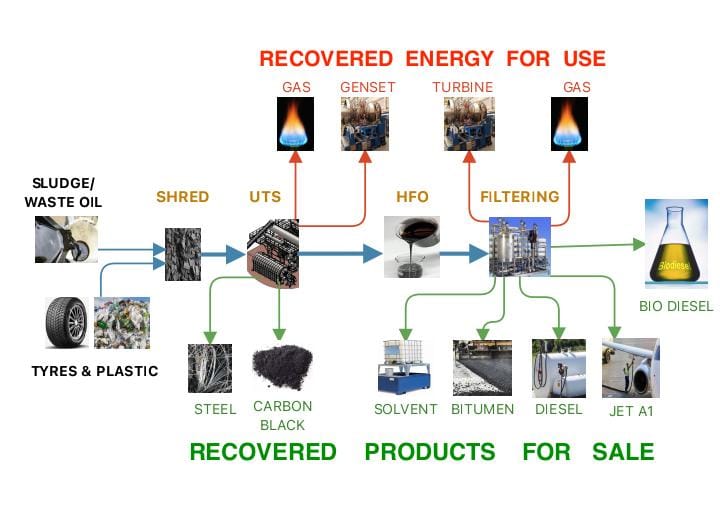

The image illustrates a waste recycling system by OnEnergy, outlining its key components, including the Reactor, Gas Burner, Blower, Gas Separator, Emission Scrubber, and more.

— The recycling process is divided into 3 stages:

Stage 1 – Shredding and Loading: Waste must be dry with no more than 5% moisture and free of metals for efficient processing. If moisture is above 5%, a pre-drying phase is necessary. Waste is fed into the chamber via a conveyor belt for manual or automated batch processing, while larger volumes (over 9 tons) utilize a continuous screw conveyor.

Stage 2 – Ultrasonic Thermolytic Synthesis: Upon entering the chamber, oxygen is expelled, and the system operates under automated vacuum control. After the process, carbon black from the reactor is sent to magnetic separators to remove steel, then ground to desired dimensions. This can be commercialized to meet specific customer needs, including washing, drying, pelletizing, and packing.

Stage 3 – thermolytic oils can undergo further filtration and enrichment using a high-tech system to meet Australian or European Standards. This optional 24-hour process is controlled by specialized software, allowing the oil to remain on-site. Ultimately, OnEnergy successfully recycles and reuses up to 99% of the original waste, capturing about 1% of impurities, preventing environmental harm